Types of Aluminum PCBs: Optimizing Thermal

Aluminum core PCBs are essential in applications where efficient thermal management is critical. Here’s an overview of the common types of aluminum PCBs, categorized by their intended use:

1. Single-Layer Aluminum PCB

A Single-Layer Aluminum PCB features a single aluminum substrate with a conductive copper layer bonded to one side. These PCBs are straightforward in design, making them ideal for applications where heat management is the primary concern. Common uses include LED lighting, automotive electronics, and power supplies, where effective heat dissipation is crucial.

2. Double-Layer Aluminum PCB

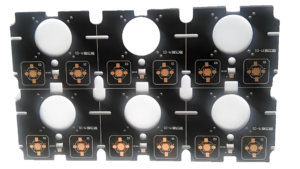

Double-Layer Aluminum PCBs consist of two aluminum substrates with a conductive copper layer bonded to both sides. This design allows for components to be placed on both sides of the board, offering enhanced design flexibility and functionality. With higher component density and the ability to create more complex circuits, these PCBs are perfect for applications that require improved thermal performance and electrical isolation, such as power converters and motor drivers.

3. Metal-Core Printed Circuit Boards (MCPCBs)

MCPCBs, or Metal-Core PCBs, feature a metal core substrate, typically made from aluminum or copper alloy, sandwiched between layers of dielectric material and copper foil. These boards offer superior thermal conductivity and heat dissipation compared to standard PCBs like FR-4, making them ideal for high-power applications. MCPCBs, also known as aluminum-clad PCBs, are available in single-layer, double-layer, and multi-layer configurations, providing flexibility for a wide range of applications.

Each type of aluminum PCB is designed to meet specific thermal management needs, ensuring optimal performance and reliability in demanding environments.

insulating dielectric material bonded to one or both sides of an aluminum substrate. The aluminum core excels at conducting heat and electricity, making these PCBs ideal for applications requiring efficient heat dissipation.

insulating dielectric material bonded to one or both sides of an aluminum substrate. The aluminum core excels at conducting heat and electricity, making these PCBs ideal for applications requiring efficient heat dissipation.