Rogers PCBs

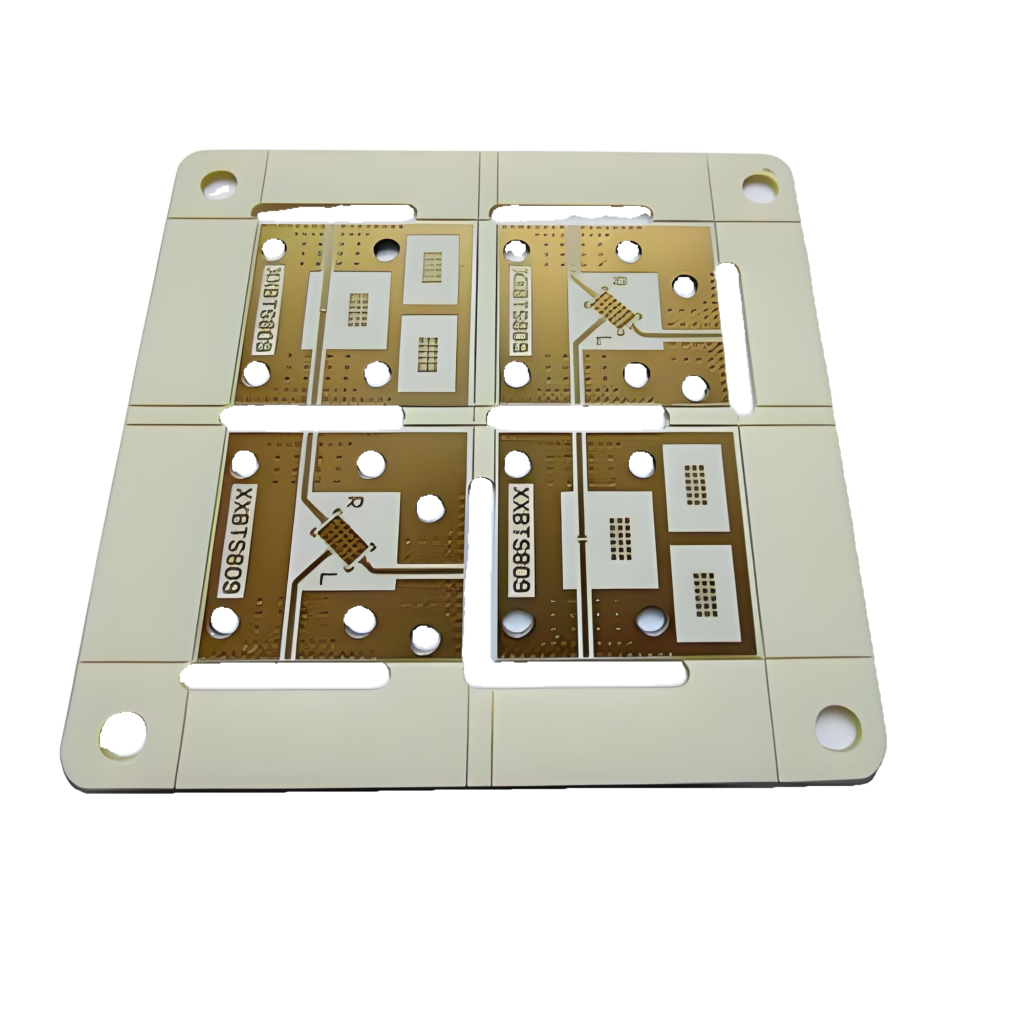

Rogers PCB Manufacturing Services

Specializing in High-Quality and Reliable Rogers PCBs

- Rogers, Rogers + FR4, Rogers + PTFE, Rogers + Metal Core Combinations

- RO4000 Series, RO3000 Series, RT/Duroid, TTM Series

- 92ML, IM Series, DiClad Series, TC Series, XtremeSpeed Series

- Precision Impedance Control Tolerance: +/- 5%

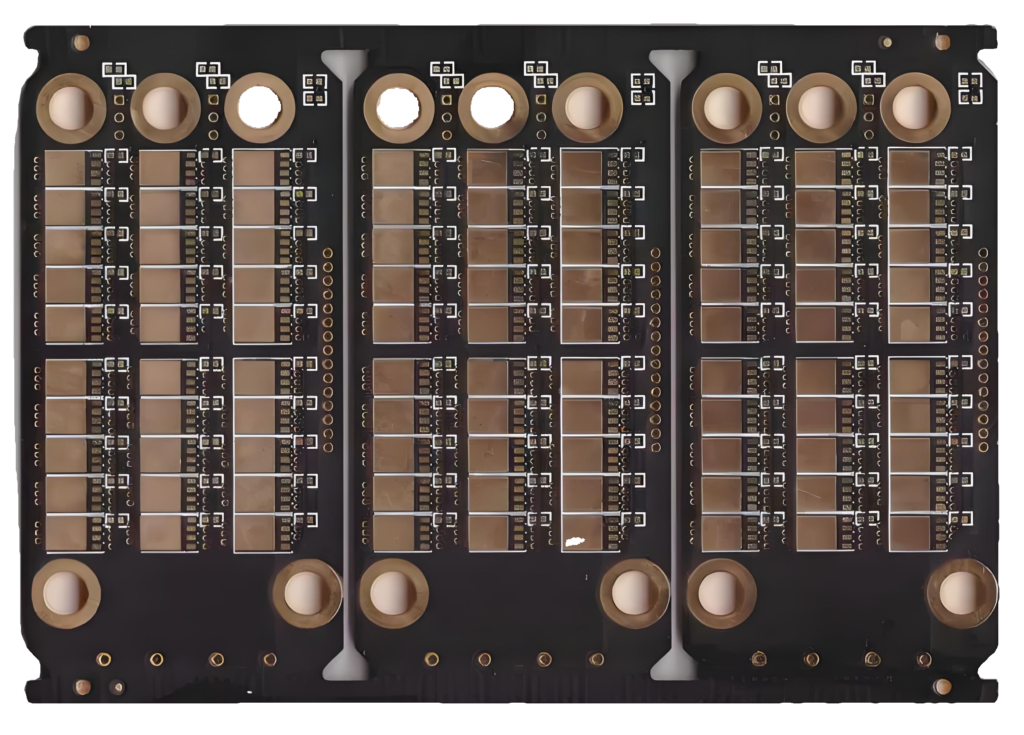

- Conductive and Non-Conductive Via Plugging

- Advanced Features: Blind & Buried Vias, Micro Vias, Any-Layer HDI

Advantages of Rogers Printed Circuit Boards

- Superior Signal Integrity: Rogers PCBs are engineered for high-speed and high-frequency signal transmission, making them ideal for advanced communication systems.

- Exceptional Electrical Performance: The dielectric materials used in Rogers PCBs offer outstanding electrical properties and chemical stability, ensuring consistent performance.

- High Reliability in Extreme Conditions: Designed to perform reliably under harsh and demanding environments, Rogers PCBs are the preferred choice for aerospace and aviation applications.

Key Properties of Rogers PCB Materials

- High Frequency and Low Loss: Rogers materials are optimized for high-frequency applications with low dielectric loss, ensuring minimal signal attenuation.

- Stable Dielectric Constant (Dk): Rogers PCBs maintain a stable dielectric constant across a wide frequency range, critical for precise and reliable signal processing.

- Versatile Dielectric Constant Range: Available in a wide range of dielectric constants to meet specific application requirements.

- Exceptional Chemical Resistance: Highly resistant to chemical exposure, Rogers materials are robust in harsh environments.

- Low Outgassing: Ideal for space applications, Rogers PCBs exhibit low outgassing properties, ensuring reliability in vacuum conditions.

Request Your Free Quote Today!

Understanding Rogers PCBs

Rogers PCBs are specialized printed circuit boards made from Rogers materials, known for their superior performance in high-frequency and RF applications. As a leading provider of advanced PCB materials, Rogers offers a wide range of products designed to meet the stringent technical requirements of modern electronics. These materials include custom grades, commercial grades, antenna-grade materials, prepregs, and adhesive films, making Rogers the go-to choice for high-performance PCBs in wired and wireless communication systems.

Rogers has pioneered breakthroughs in the field of high-frequency and high-performance PCBs, playing a critical role in the advancement of global communication technology. Key applications of Rogers PCBs include high-frequency electronics, wireless base stations, aerospace and defense systems, automotive electronics, and high-speed digital applications.

For example, the Rogers RO4000 series is a standout material designed for high-frequency PCB applications. Unlike standard PCB materials like PTFE, the RO4000 series offers low loss, tight tolerance, and exceptional high-frequency performance. It also features stable electrical properties across different frequencies, a low dielectric constant temperature coefficient, and excellent dimensional stability, making it ideal for mass production. These materials are commonly used in satellite TV LNBs, microstrip line products, cellular base station antennas, power amplifiers, spread spectrum communication systems, RFID labels, and more.

At LEAPPCB, we provide a wide range of Rogers PCB materials, including Rogers 4003, Rogers 4350, Rogers 5880, RO3003, RO6002, Rogers FR4, TTM10, Rogers ceramic, Rogers PTFE, and others. With our strong engineering, procurement, production, and quality teams, we are one of the most trusted Rogers PCB manufacturers in China. Feel free to contact us for any Rogers PCB inquiries or quotes.

Rogers PCB Applications

Rogers PCBs are predominantly utilized in advanced and high-performance applications. The most commonly used Rogers materials include RO4350B, RO4003C, and Rogers3003, which are selected for their superior electrical properties and reliability.

Key Applications of Rogers PCBs:

- Automotive Safety Systems: Integral to automotive anti-collision systems, ensuring rapid and reliable communication between sensors and control units.

- Satellite and Communication Systems: Widely used in satellite systems, radio systems, and radar, where high-frequency performance is critical.

- Cellular and Wireless Infrastructure: Essential for cell phone base stations and the broader communication industry, supporting high-speed data transmission and network reliability.

- Advanced Network Technology: Facilitates the advancement of network technologies and high-speed information processing systems.

Rogers PCB Material Properties:

- Active Safety Systems: Supports critical safety functions in automotive and aerospace applications.

- Antenna Systems: Provides excellent performance for various antenna applications, including those in wireless and Wi-Fi systems.

- Communication Systems: Ideal for use in high-frequency communication systems and power amplifiers.

- Telematics and Infotainment: Enhances the functionality of telematics and infotainment systems in modern vehicles.

- Computing & IP Infrastructure: Supports high-speed computing and IP infrastructure applications.

- Test & Measurement: Ensures precision in test and measurement equipment, crucial for quality assurance and system diagnostics.

Advantages of PCB Boards Made with Rogers Materials

Optimal Choice for RF Applications: Rogers is renowned for its specialization in developing and producing materials for Radio Frequency (RF) PCBs. The unique and superior parameters of Rogers products often have no equivalent alternatives from other suppliers, making them the top choice for RF applications.

Exceptional Mechanical and Electrical Performance: Rogers materials offer outstanding mechanical and electrical properties, including easy hole metallization and high precision in material thickness. The copper used in Rogers PCBs is particularly noteworthy for its excellent adhesion, superior heat dissipation, and exceptional peel strength. These qualities are crucial for achieving high-quality production and yield rates, making Rogers materials highly recommended by leading PCB manufacturers like LEAPPCB.

Consistent Quality: As a leader in RF PCB material research and production, Rogers has established a reputation for producing consistently high-quality products over many years of mass production. This reliability makes Rogers the preferred choice for customers who value stable performance and are reluctant to switch to new suppliers.

Cost-Effective Solution: While Rogers RF high-frequency PCB materials are more expensive than standard FR4 materials, their superior quality and high-frequency performance make them a cost-effective solution, especially with the Rogers RO4000 series. Additionally, some Rogers materials are compatible with FR-4 production technology, which can help reduce overall production costs.

Classification of Rogers PCB Materials

Rogers materials are specialized for high-frequency and high-speed applications. Based on their dielectric constant, these materials are categorized into high dielectric constant (Dk) and low dielectric constant (Dk) types. Understanding these classifications is crucial for effective Rogers PCB fabrication.

1. High Dielectric Constant (Dk) Materials

- Ceramic Hydrocarbon: TMM® 6, TMM 10, TMM 10i

- Ceramic PTFE: RT/duroid® 6006, RT/duroid 6010LM, RO3006™, RO3010™, RO3210™

2. Low Dielectric Constant (Dk) Materials

- Ceramic Hydrocarbon: TMM 3, TMM 4, RO4003C®, RO4350B®, RO4350i

- Ceramic PTFE: RT/duroid 6002, RT/duroid 6202, RO3003™, RO3035™, RO3203™

- Non-Woven Glass PTFE: RT/duroid 5870, RT/duroid 5880

- Woven Glass PTFE: ULTRALAM® 2000

Your Trusted Partner for Rogers PCBs - LEAPPCB

Popular Rogers PCB Materials

Rogers is a leading provider of advanced PCB materials, particularly known for their exceptional performance in signal integrity, thermal management, and power distribution. Among the various materials they offer, the following high-frequency PCB materials are commonly used. As one of the top Rogers PCB suppliers in China, we provide boards using all these materials.

RO4003

- Dielectric Constant (Dk @ 10GHz): 3.38 ± 0.05

- Dissipation Factor (Df @ 1GHz): 0.0027

- Coefficient of Thermal Expansion (PPM/°C): X: 11, Y: 14, Z: 46

- Thermal Conductivity (W/m*K): 0.64

RO4350

- Dielectric Constant (Dk @ 10GHz): 3.48 ± 0.15

- Dissipation Factor (Df @ 1GHz): 0.0037

- Coefficient of Thermal Expansion (PPM/°C): X: 14, Y: 16, Z: 35

- Thermal Conductivity (W/m*K): 0.62

Note: RO4350 is an upgraded version of RO4003, with enhanced flame retardancy. The RO4000 series is the most widely used high-frequency PCB material, making Rogers RO4350B and RO4003C common choices in the industry.

RT5870

- Dielectric Constant (Dk @ 10GHz): 2.33 ± 0.02

- Dissipation Factor (Df @ 1GHz): 0.0012

- Coefficient of Thermal Expansion (PPM/°C): X: 22, Y: 28, Z: 173

- Thermal Conductivity (W/m*K): 0.22

RT5880

- Dielectric Constant (Dk @ 10GHz): 2.20 ± 0.02

- Dissipation Factor (Df @ 1GHz): 0.0009

- Coefficient of Thermal Expansion (PPM/°C): X: 31, Y: 48, Z: 237

- Thermal Conductivity (W/m*K): 0.20

RT6002

- Dielectric Constant (Dk @ 10GHz): 2.94 ± 0.04

- Dissipation Factor (Df @ 1GHz): 0.0012

- Coefficient of Thermal Expansion (PPM/°C): X: 16, Y: 16, Z: 24

- Thermal Conductivity (W/m*K): 0.60

RT6006

- Dielectric Constant (Dk @ 10GHz): 6.15 ± 0.15

- Dissipation Factor (Df @ 1GHz): 0.0027

- Coefficient of Thermal Expansion (PPM/°C): X: 47, Y: 34, Z: 117

- Thermal Conductivity (W/m*K): 0.48

RT6010

- Dielectric Constant (Dk @ 10GHz): 10.2 ± 0.25

- Dissipation Factor (Df @ 1GHz): 0.0023

- Coefficient of Thermal Expansion (PPM/°C): X: 24, Y: 24, Z: 24

- Thermal Conductivity (W/m*K): 0.78

TMM3

- Dielectric Constant (Dk @ 10GHz): 3.27 ± 0.02

- Dissipation Factor (Df @ 1GHz): 0.0020

- Coefficient of Thermal Expansion (PPM/°C): X: 16, Y: 16, Z: 20

- Thermal Conductivity (W/m*K): 0.70

TMM4

- Dielectric Constant (Dk @ 10GHz): 4.5 ± 0.0045

- Dissipation Factor (Df @ 1GHz): 0.0020

- Coefficient of Thermal Expansion (PPM/°C): X: 14, Y: 14, Z: 20

- Thermal Conductivity (W/m*K): 0.70

TMM6

- Dielectric Constant (Dk @ 10GHz): 6.00 ± 0.08

- Dissipation Factor (Df @ 1GHz): 0.0023

- Coefficient of Thermal Expansion (PPM/°C): X: 16, Y: 16, Z: 20

- Thermal Conductivity (W/m*K): 0.72

TMM10

- Dielectric Constant (Dk @ 10GHz): 9.20 ± 0.23

- Dissipation Factor (Df @ 1GHz): 0.0022

- Coefficient of Thermal Expansion (PPM/°C): X: 16, Y: 16, Z: 20

- Thermal Conductivity (W/m*K): 0.76

TMM10i

- Dielectric Constant (Dk @ 10GHz): 9.80 ± 0.245

- Dissipation Factor (Df @ 1GHz): 0.0020

- Coefficient of Thermal Expansion (PPM/°C): X: 16, Y: 16, Z: 20

- Thermal Conductivity (W/m*K): 0.76

Get Your Free Instant Quote Today!

Leap Electronic is your trusted partner and one-stop shop for PCB fabrication, component sourcing, PCB assembly, and electronic manufacturing. With over 16 years of expertise, we proudly serve over 1000 customers worldwide, delivering top-quality PCBs at competitive prices. Our ISO9001:2015 certification and UL listing ensure that all our products meet the highest industry standards. Every PCB is 100% E-tested and inspected using AOI and X-RAY, guaranteeing unparalleled reliability and performance.

Don’t wait – get an instant quote from our sales team today and experience the Leap Electronic difference. We’ll handle the rest!

Everything You Need to Know About Rogers PCBs

Rogers PCBs are circuit boards made from advanced Rogers materials, renowned for their superior performance in high-frequency applications. The most commonly used materials include Rogers 4350B, Rogers 4003C, and Rogers 3003.

Utilizing advanced PCB materials is crucial for supporting next-generation designs, as they help minimize dielectric losses and reduce electrical signal losses. This results in PCBs with exceptional high-frequency and high-speed performance.

- Rogers Company is a global leader in high-performance PCB materials, specifically designed for microwave and RF printed circuit boards. Virtually all Rogers PCBs are well-suited for high-frequency applications.

For high-moisture environments, low moisture absorption PCB materials are essential. Rogers materials are particularly advantageous in these conditions due to their resistance to chemicals, moisture, and high temperatures, as well as their excellent peel strength, ensuring powerful performance in high-frequency circuit boards.

Rogers FR4 circuit boards are multilayer PCBs that combine Rogers materials with FR4 materials. Typically, Rogers materials are used for the outer layers, with RO4350B, RO4003C, and Rogers 3003 being the most common choices for these types of circuits.

The superiority of Rogers vs. FR4 boards depends on the application. For microwave and RF devices, Rogers PCBs offer significant advantages. However, FR4 materials are also highly reliable and cost-effective, making them a good choice for other applications.

The choice of materials depends on the specific requirements of the PCB. For general purposes, FR-4 materials are commonly used. For high-frequency PCBs, Rogers materials like Rogers 4350 and Rogers 4003 are preferred.

Yes, we provide quick-turn services for Rogers PCBs. We strive to meet your deadlines and deliver Rogers PCB products according to your specifications. We typically keep a stock of Rogers RO4350B and Rogers RO4003C materials to expedite production.

Absolutely, Rogers PCBs are highly suitable for space microwave and RF applications, with Rogers materials being among the best choices in this field.

The available foil types for metal claddings in Rogers PCBs include:

- Electrodeposited Foil

- Rolled Foil

- Resistive Foil

- Electrodeposited Reverse Pickled/Treated Metal Cladding

Yes, we provide custom Rogers PCBs tailored to your specific requirements. The most commonly used materials include RO4350B, RO4003C, and RO3003. We are committed to delivering high-quality products at competitive prices and look forward to serving your needs!