Blind and Buried Vias PCBs

Expertise in PCB Manufacturing

- Specializing in 1-100 Layer Rigid and Rigid-Flex PCBs for Prototypes

- Advanced Capabilities Including Blind & Buried Vias, Stacked & Staggered Vias, and Any-Layer HDI

- Expertise in Microvias, VIPPO (Via In Pad Plated Over), and Via Plugging with Conductive & Non-Conductive Materials

- Proficient in Backdrilling, Backplane Design, Embedded Devices, and IC Substrate Manufacturing

- ISO 9001:2015 and ISO 13485:2016 Certified & UL Listed for Quality Assurance

Understanding the Difference Between Blind and Buried Vias

Blind and buried vias are specialized features used in multilayer PCBs to optimize connectivity and save space.

Blind Vias: These vias connect the outer layers of the PCB (top or bottom) to one or more inner layers without extending through the entire board. The depth of a blind via is typically controlled to maintain a specific aspect ratio, ensuring a reliable connection between the surface layer and the internal circuitry. Blind vias do not pass through the entire board, making them ideal for high-density designs where space on the outer layers is at a premium.

Buried Vias: In contrast, buried vias are entirely contained within the inner layers of the PCB, connecting different internal layers without reaching the outer surfaces. These vias are completely hidden from view once the PCB is fully assembled, as they do not extend to either the top or bottom layers. Buried vias are used to increase the complexity and functionality of the PCB without affecting the board’s surface area, making them crucial in advanced, multilayer designs.

Request Your Free Quote Today!

The Emergence of Blind and Buried Vias in PCB Fabrication

Blind and buried vias are specialized features in printed circuit boards (PCBs) designed to optimize space and performance in high-density applications.

- Plated Through-Holes (PTH): These are vias that extend from the top to the bottom layer of the PCB.

- Blind Vias: These connect an outer layer (either the top or bottom) to one or more inner layers but do not go through the entire board.

- Buried Vias: These are entirely embedded within the inner layers of the PCB and are not visible from the outside after manufacturing.

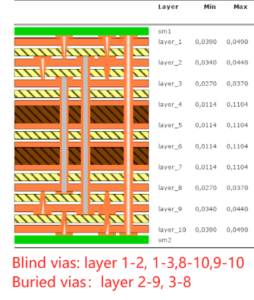

For instance, in a 6-layer HDI PCB, you might find blind vias connecting layers 1 and 2, buried vias linking layers 3 and 4, and PTHs running from layer 1 to layer 6.

Blind and buried vias are essential in high-density interconnect (HDI) PCBs, as they save space, enhance electromagnetic compatibility (EMC), and improve signal integrity. Their use is crucial in complex circuit designs, allowing the PCB to support more intricate circuitry and broadening its range of applications.

Understanding Buried Vias in PCBs

Buried vias are an integral feature of blind and buried via PCBs, specifically designed to connect inner layers of a printed circuit board (PCB) without extending to the outer layers. These vias are completely encapsulated within the inner layers, making them invisible once the PCB is laminated.

For instance, in a 6-layer PCB with blind and buried vias, connections such as those between layers L2-L3, L2-L4, L2-L5, L3-L4, L3-L5, and L4-L5 are considered buried vias. Since these vias are “buried” within the board, the term “buried vias” aptly describes them, and the corresponding PCBs are referred to as buried via PCBs.

Complexity and Cost of Buried Via PCBs

The production of buried via PCBs is more complex than that of traditional multilayer PCBs, leading to higher manufacturing costs. Unlike conventional multilayer PCBs, which are drilled after lamination, buried via PCBs require a different approach. The drilling of vias in buried via PCBs occurs before the final lamination process, targeting specific inner layers.

This process involves drilling and plating the vias within the designated inner layers, followed by partial lamination. Afterward, the full lamination of the entire PCB is completed. Due to the intricate steps involved—such as precise drilling, selective plating, and staged lamination—manufacturing buried via PCBs is more time-consuming and costly.

However, this advanced process significantly enhances space utilization within the PCB, making buried via PCBs an ideal choice for high-precision and high-density applications where maximizing available space is crucial.

Understanding Blind Vias in PCBs

Blind vias are a critical feature in advanced PCB design, connecting the outer layer of the board to one or more inner layers without extending through the entire board. In a typical 6-layer PCB, for example, vias connecting layers L1-L2, L1-L3, L1-L4, L1-L5, L2-L6, L3-L6, L4-L6, and L5-L6 are considered blind vias. These vias are termed “blind” because they connect the surface to internal layers without being visible on the opposite side of the board. Consequently, PCBs incorporating these features are known as blind via PCBs.

Advantages of Blind Vias

The use of blind and buried vias is an effective strategy to increase the density of multilayer PCBs, enabling more complex designs while reducing the overall layer count and dimensions of the board. By incorporating blind and buried vias, PCB manufacturers can significantly reduce the number of traditional plated through-holes, leading to more compact and efficient circuit layouts. This technique is commonly employed in Build-Up Multilayer (BUM) PCBs, which heavily rely on blind and buried vias to achieve high-density interconnects.

Microvias and Advanced Drilling Techniques

Most blind and buried vias in modern PCBs have very small diameters, typically ranging from 0.05 mm to 0.15 mm. Due to their size, these are often referred to as microvias, and the corresponding PCBs are known as microvia PCBs. While buried vias are typically produced in the same manner as double-sided PCBs, blind vias require more advanced techniques.

Blind vias are typically created using a CNC machine that precisely controls the drilling depth along the z-axis. However, with the continuous advancement of technology, laser drilling has become increasingly prevalent. This method uses highly focused lasers, such as carbon dioxide lasers, excimer lasers, and YAG ultraviolet lasers, to precisely drill blind vias.

For instance, the Hitachi carbon dioxide laser machine, known for its efficiency, operates at a wavelength of 9.4 nm and can drill a single blind via in three passes. This machine is capable of drilling up to 30,000 blind vias per minute, making it an incredibly efficient solution for high-density PCB manufacturing.

The Role of Blind Vias in High-Density PCB Design

As electronic devices continue to evolve towards higher density and precision, the demand for corresponding PCBs increases. Blind and buried vias play a crucial role in meeting these demands by reducing the number of traditional plated through-holes and enabling more complex, compact designs. Accurate implementation of these vias is essential for achieving the desired performance and reliability in high-density PCBs.

Laser Drilling in Blind and Buried Vias PCBs

Laser drilling technology has become a cornerstone in modern PCB manufacturing, particularly for blind and buried vias. This advanced technology offers numerous benefits, including high precision, versatility, efficiency, and cost-effectiveness. As a result, laser drilling is now one of the key technologies in producing high-density interconnect (HDI) PCBs with blind and buried vias.

Before the advent of laser technology, drilling holes in materials with high hardness, such as diamonds, was a challenging and time-consuming process. Traditional mechanical drilling methods were limited to punching holes in materials of lower hardness. However, laser drilling revolutionized this process, enabling rapid and safe hole creation in even the toughest materials used in PCB manufacturing.

While laser-drilled holes are typically conical rather than cylindrical, which can be less ideal in certain applications, the overall advantages of laser drilling—such as programmable control, high accuracy, and efficiency—far outweigh this drawback.

How Laser Drilling Works:

Laser drilling involves focusing a laser beam into a high-intensity heat source, which is then directed at the material to be drilled. The intense heat causes the material in the laser’s path to melt, vaporize, and eventually evaporate, creating a hole. The laser beam’s high concentration in both space and time allows for precise control, enabling the creation of holes in almost any material. With power densities reaching up to 10^15 W/cm², laser drilling is a powerful tool for PCB manufacturing.

Key Characteristics of Laser Drilling in HDI PCBs:

- Aperture Size: Laser-drilled holes typically range from 4 to 6 mils in diameter.

- PP Thickness: The prepreg (PP) thickness should be ≤ 4.5 mils, with an aspect ratio ≤ 0.75:1.

- Material Options: Suitable materials for laser drilling include LDPP (106/1080), FR4 (106/1080), and RCC.

- High Depth-to-Diameter Ratio: Laser drilling can achieve a large depth-to-diameter ratio, essential for high-density PCB designs.

- Tool-Free Operation: As a non-contact machining process, laser drilling eliminates the risk of tool breakage, a common issue in mechanical drilling.

- Group Hole Machining: Laser drilling is ideal for creating large quantities of high-density group holes, making it highly efficient for complex PCB designs.

In summary, laser drilling technology has significantly enhanced the capabilities of PCB manufacturing, particularly in the production of blind and buried vias. Its precision, efficiency, and adaptability make it an indispensable tool in the industry.

Electroplating Blind and Buried Vias

In PCB manufacturing, the electroplating process for blind and buried vias requires careful consideration to ensure optimal results. Below are key guidelines for electroplating blind vias under various conditions:

Typically, a layer of copper undergoes one round of whole-board electroplating followed by one round of pattern plating. This is standard for most PCB layers.

For boards with a thickness greater than or equal to 80 mils, and when through-hole plating is required, both whole-board electroplating and pattern plating are necessary. However, during the blind via plating process, whole-board electroplating cannot be applied to the outer layers.

- If the outer layer trace width is greater than 6 mils, and the PTH board thickness is less than 80 mils: The outer layer can undergo whole-board electroplating during the blind via electroplating process.

- If the outer layer trace width is greater than 6 mils, but the PTH board thickness is greater than 80 mils: The outer layer should be protected by applying a film over the surface during the blind via electroplating process.

- If the outer layer trace width is less than 6 mils and the PTH board thickness is greater than or equal to 80 mils: Similar to the previous scenario, the outer layer must be protected with a film during electroplating to avoid damage and ensure proper plating of the blind vias.

Benefits of Using Blind and Buried Vias

Increased Density and Reduced Board Size: Incorporating blind and buried vias into PCB designs is an efficient way to enhance the density of multilayer boards. This approach reduces the overall number of layers and board dimensions, significantly cutting down the need for plated through holes.

Enhanced Reliability and Signal Integrity: Blind and buried vias improve PCB reliability by providing better control over characteristic impedance, reducing crosstalk, noise, and signal distortion. These features are critical in high-performance and high-frequency applications.

Optimized Space Utilization: The use of blind and buried vias frees up valuable space on the PCB, allowing for more compact designs without compromising the surface components or routing on the top and bottom layers.

Blind and buried vias are designed to connect outer and inner layers of a PCB while preserving valuable surface area. The depth of these vias is carefully controlled, typically not exceeding the diameter of the hole, to ensure proper plating and connection.

The fabrication process for blind and buried vias in PCBs involves several methods:

Mechanical Specified Depth Drilling:

- Traditional multilayer PCBs are processed up to the lamination stage. The drilling machine is then set to a specific z-axis depth to create blind and buried vias.

- While this method is relatively straightforward, it has limitations, such as low output efficiency and challenges in controlling consistent hole depth, making it less suitable for mass production.

Sequential Lamination:

- Example: In an 8-layer PCB, the inner layers (L3-L6) are fabricated as a standard 4-layer PCB, while the blind vias (L1-L2, L7-L8) are produced as separate double-sided PCBs.

- Process:

- Laminate the inner 4-layer PCB with the two double-sided PCBs.

- Drill and plate through-holes, followed by copper plating and solder mask application.

- For complex designs with both blind and buried vias on the same layer, laser drilling is required in multiple lamination steps.

Any Layer Lamination and Drilling:

- This method is widely adopted in the global PCB industry, particularly for high-density interconnect (HDI) designs.

- Process:

- Layers are added sequentially from the innermost to the outermost layer. Laser drilling is used to create stacked or staggered micro vias, depending on design requirements. This process results in what is known as “any layer PCB.”

Photo-Defined Type:

- Photosensitive resistance and a permanent media layer are applied simultaneously. The desired locations are exposed and developed using a negative film to create a bowl-shaped blind hole, which is then plated with copper or filled with conductive paste.

Plasma Etching:

- A patented process used by certain companies for precise etching of vias.

Laser Ablation:

- This includes methods like CO2 laser, excimer laser, and Nd: YAG laser, commonly used in HDI PCB manufacturing for their precision and efficiency.

One straightforward method to identify blind and buried vias in PCB Gerber files is to examine the number of drilling files included in the data. If you encounter more than two drilling files, it’s likely that the PCB design incorporates blind and buried vias.

For instance, in a 4-layer PCB, you might find multiple drilling files such as TXT1, TXT2, TXT3, TXT4, drl1-2, drl3-4, and drl1-4. The presence of these files suggests the use of blind and buried vias within the PCB.

Why Choose LEAPPCB as Your Blind and Buried Vias PCBs Partner?

Unmatched Capabilities

LEAPPCB specializes in providing a comprehensive range of rigid PCB solutions, accommodating various materials, layer counts, copper thicknesses, surface finishes, and technologies. Whether you require a straightforward one-layer PCB or a complex 100-layer HDI PCB with intricate vias and fine lines, we have the expertise to fulfill all your needs.

Competitive Pricing

We offer competitive pricing with flexible options tailored to your requirements. Share your technical specifications with us, and we will promptly provide you with a detailed quotation.

Superior Quality

Quality is at the heart of everything we do at LEAPPCB. Our commitment to delivering high-quality rigid PCBs is unwavering, driven by a zero-defect mindset and a culture of continuous improvement. Our production processes adhere to stringent quality management standards, including ISO9001, ISO13485, and TS16949.

Exceptional Customer Service

At LEAPPCB, we believe that open communication and collaboration are the keys to a successful partnership. We treat our customers as partners, aligning our goals with yours to ensure your success. We prioritize your needs and requests, delivering on our commitments every time.

Fast and Reliable Delivery

We are known for our reliability in meeting delivery deadlines. LEAPPCB offers fast turnaround times and expedited options to ensure your projects stay on track. Our adherence to delivery commitments is a testament to our dedication to your success.

Choose LEAPPCB for your rigid PCB needs and experience unparalleled service, quality, and expertise. Contact us today to discuss your project requirements!

Get Your Free Instant Quote Today!

Leap Electronic is your trusted partner and one-stop shop for PCB fabrication, component sourcing, PCB assembly, and electronic manufacturing. With over 16 years of expertise, we proudly serve over 1000 customers worldwide, delivering top-quality PCBs at competitive prices. Our ISO9001:2015 certification and UL listing ensure that all our products meet the highest industry standards. Every PCB is 100% E-tested and inspected using AOI and X-RAY, guaranteeing unparalleled reliability and performance.

Don’t wait – get an instant quote from our sales team today and experience the Leap Electronic difference. We’ll handle the rest!

Everything You Need to Know About Blind and buried Vias PCBs

Blind Vias: Blind vias are vias that connect an outer layer of the PCB to one or more inner layers but do not pass through the entire board.

Buried Vias: Buried vias are entirely enclosed within the inner layers of the PCB and are not visible from the outer surfaces.

Blind and buried vias are typically utilized in high-tech electronic circuit boards where complex functionalities are combined into a compact area, such as in mobile phone PCBs. These types of vias are common in High-Density Interconnect (HDI) PCBs, which feature small drill holes and fine trace widths.

Blind and buried vias can be created using the following methods:

- Mechanical Drilling with Fixed Depth

- Sequential Lamination and Drilling

- Any Layer Lamination and Drilling

Blind and buried vias are filled with materials such as non-conductive resin or conductive materials like copper to enhance reliability and performance.

For laser-drilled blind vias, the process is as follows:

- Complete the fabrication of all inner layers.

- Laminate two outer layers of prepreg and copper sheet onto the completed inner layers.

- Drill the controlled depth blind vias using a laser. Accuracy is crucial for blind vias, especially when using via-in-pad designs.

For mechanically drilled blind vias, such as in a 4-layer PCB with blind vias between layers 1 and 2, the process is:

- Fabricate layers 1 and 2 as a standard 2-layer PCB, including drilling between these layers.

- Laminate the two core boards together to form the 4-layer PCB and drill the plated through holes.

- After finishing, the PCB will have PTH vias from layers 1 to 4 and blind vias from layers 1 to 2.

- Size and Weight Reduction: Helps minimize the overall size and weight of the PCB.

- Layer Reduction: Reduces the number of layers required.

- Cost Efficiency: Lowers production costs by integrating more functions into fewer layers.

- Enhanced Electromagnetic Compatibility: Improves signal integrity and reduces interference.

- Improved Design Flexibility: Simplifies and accelerates the design process.

- Enhanced Product Characteristics: Boosts the overall performance and reliability of electronic products.

- Miniaturization: Smaller via diameters require more advanced manufacturing techniques.

- Design Complexity: Requires highly experienced engineers to design effectively.

- Assembly Challenges: Tiny pads, such as those used in BGA components, make assembly more difficult.

For laser-drilled blind vias, the standard aspect ratio is typically 1:1.

The cost of adding blind vias to a PCB can increase the total cost by approximately 10-20%, depending on the complexity and number of vias.

- Blind Vias: Connect an outer layer to an inner layer without passing through the entire PCB.

- Buried Vias: Connect inner layers only, with no connection to the outer layers, and are not visible from the outside.