Material Selection and Optimization

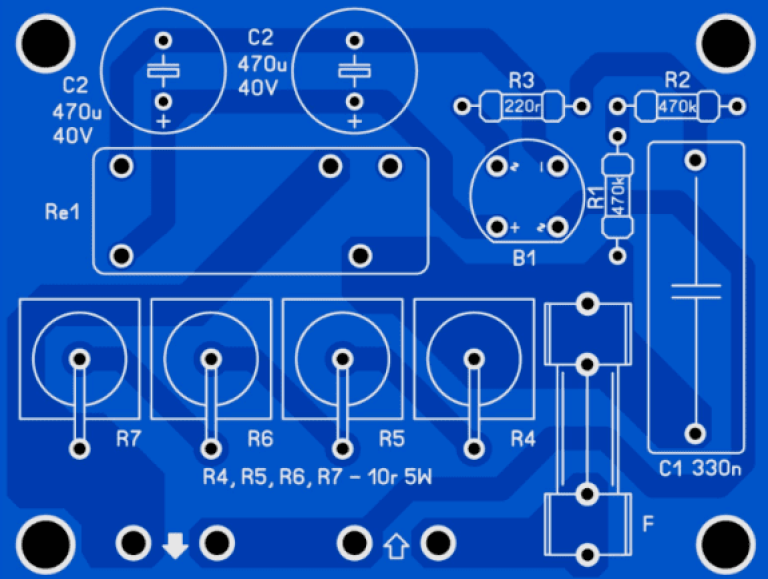

In some instances, material changes are necessary due to factors such as extended lead times or the discontinuation of a specific material type or thickness. When this occurs, we will recommend an appropriate substitute and seek your approval to ensure the change aligns with your project’s requirements.

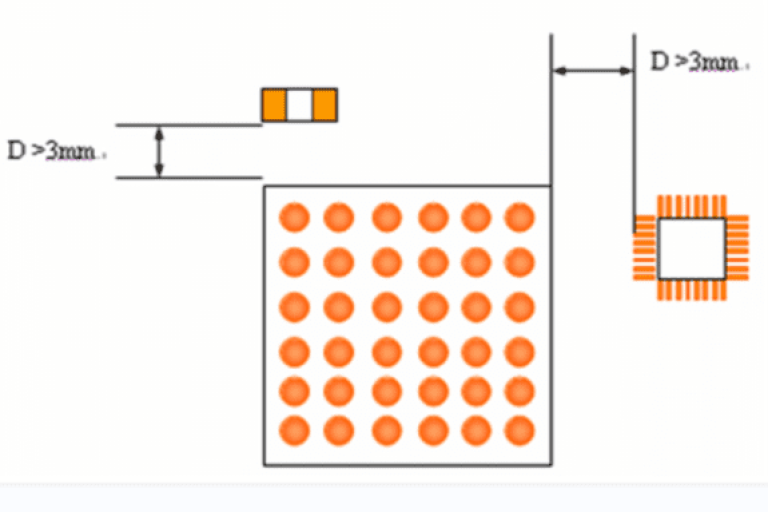

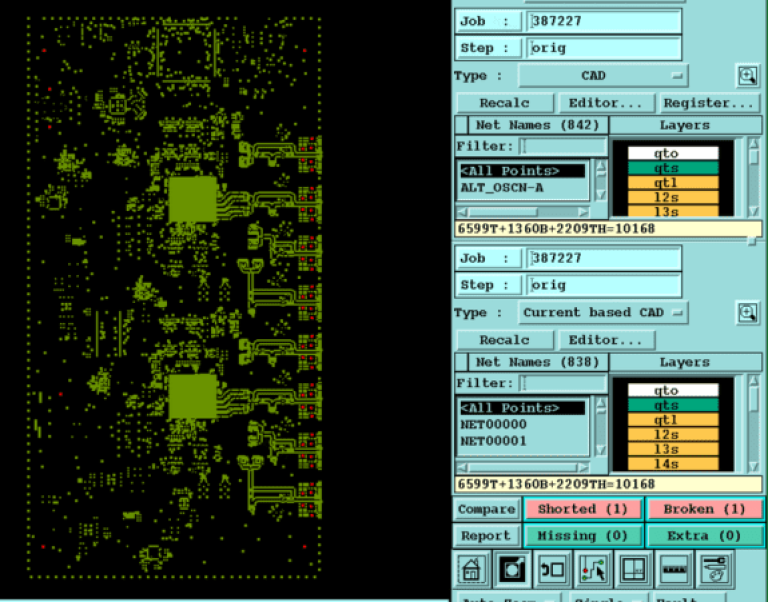

To optimize costs and maximize material utilization, we employ advanced software to determine the most efficient array style and size. This approach typically achieves a minimum of 85% utilization for single or double-sided boards and at least 75% for multi-layer boards. This careful planning ensures that we deliver cost-effective solutions without compromising on quality or performance.