Customer-Provided Samples (Optional)

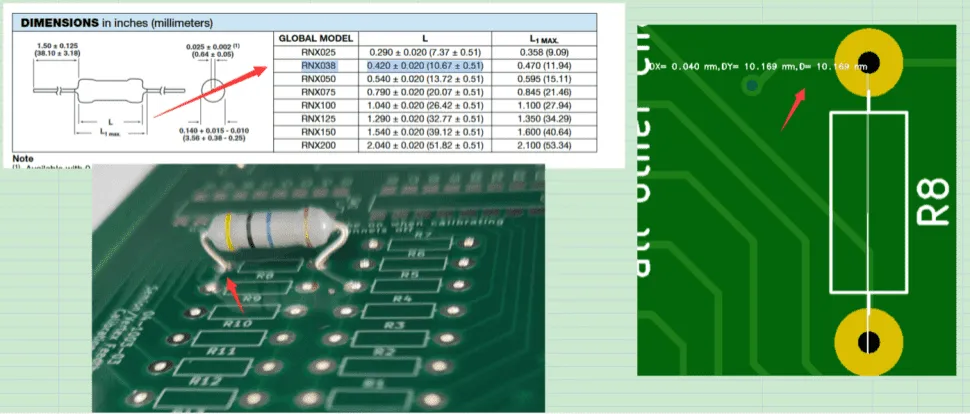

Customer-provided samples serve as valuable references for the PCB assembly (PCBA) process. These samples can guide the assembly team on various aspects, such as the correct polarity of components, the amount of solder on joints, spray codes, markings, and the application of conformal coatings. While not always required, having a sample can be particularly useful for ensuring accuracy, especially in batch orders. If no sample is available, producing a few sample units for testing before full-scale production can be an effective alternative.

Process Guidance Documentation

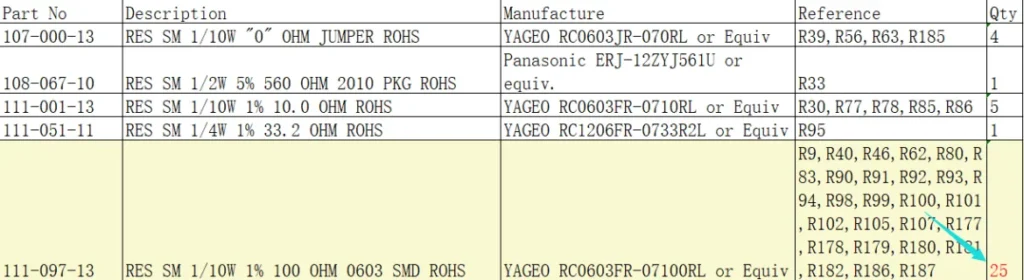

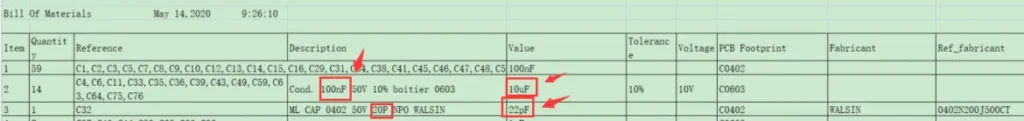

To ensure the highest quality during PCBA, customers often provide specific process guidance documents. These documents detail any special requirements or design considerations that must be followed during assembly. If the requirements are minimal, customers may include notes directly in the BOM file. For example, specific instructions for soldering lines or applying conformal coatings may be provided to meet the product’s unique demands.

Test Documentation

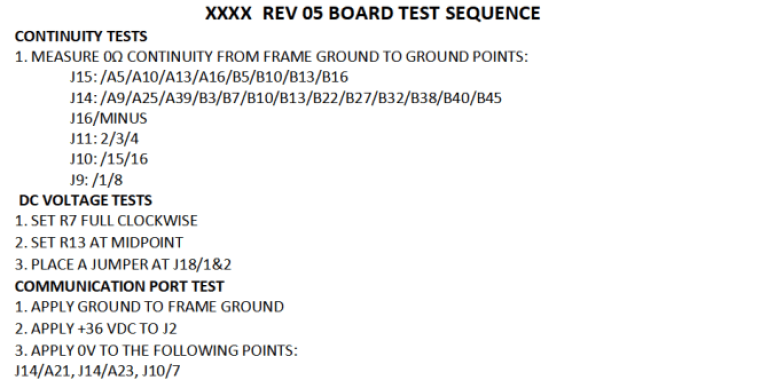

After completing the PCBA process, rigorous testing is essential to ensure that the final product meets all specified requirements. Customers typically provide detailed test documentation outlining the various test projects, parameters, and technical indicators that the assembled boards must pass. These documents guide the design and implementation of test fixtures and procedures, ensuring that each product undergoes thorough functional testing to verify its performance and reliability.