Metal Core PCBs

Metal Core PCBs at Competitive Prices

- Diverse Substrate Options: Aluminum, Copper, and Iron Substrates available.

- Versatile Layering: Choose from Single-layer, Double-layer, and Multilayer configurations.

- Exceptional Thermal Conductivity: Built with high thermal conductivity materials for optimal performance.

- Advanced Stack-Up Options: Offering both standard stack-up and thermoelectric separation.

- Certified Quality: ISO9001:2015 Certified & UL Listed for guaranteed reliability.

- Comprehensive Testing: Every PCB undergoes 100% E-testing, AOI inspection, and visual inspection.

Why Choose Metal Core PCBs?

When your PCB needs demand exceptional thermal management, robust mechanical strength, and a lightweight design, Metal Core PCBs—also known as thermal PCBs—are the ideal solution. These specialized PCBs are engineered to handle the toughest conditions, ensuring reliability and performance in even the most demanding applications.

Request Your Free Quote Today!

Understanding Metal Core PCBs

Metal core PCBs are a specialized type of circuit board that use a metal substrate, such as aluminum, copper, or special alloys, as their base material—unlike the FR4 typically found in general-purpose PCBs. These metals offer superior heat dissipation, making them ideal for applications where managing heat generation is critical.

Copper is commonly used in metal core PCBs, but modern advancements have introduced lighter and more cost-effective alloys that resist corrosion. These PCBs are perfect for scenarios where heat needs to be efficiently managed, but the circuit design does not require complex, multi-layer stackups. The primary goal is to quickly and evenly dissipate heat across and away from the board, ensuring optimal performance and longevity.

Unlock the Technical Advantages of Metal Core PCBs

Metal core PCBs, particularly those with copper or aluminum cores, offer several advantages over traditional FR4-based PCBs. Here’s why they stand out:

1. Reduced Weight

Metal core PCBs, often using aluminum as the core, are significantly lighter than their FR4 counterparts. This weight reduction is especially beneficial in applications where minimizing overall weight is crucial.

2. Superior Heat Management

One of the key advantages of metal core PCBs is their exceptional thermal management. The metal core efficiently spreads heat across the PCB, allowing it to dissipate faster and more evenly. This eliminates the need for additional thermal pastes or heat sinks, enhancing the overall performance and longevity of the components.

3. Increased Durability

The presence of a metal core enhances the ruggedness and durability of the PCB, making it more resistant to mechanical stress and environmental factors.

4. Eco-Friendly and Recyclable

Metal core PCBs are also environmentally friendly. The metal core can be recycled, and when disposed of, it does not contribute to soil toxicity, making them a sustainable choice.

These advantages make metal core PCBs an excellent option for applications requiring lightweight, durable, and thermally efficient circuit boards.

Exploring the Four Main Types of Metal Core PCBs

Metal Core PCBs (MCPCBs) are a unique category of circuit boards, distinguished by their metal cores, typically made from aluminum, aluminum alloys, or copper. These cores are combined with dielectric layers and copper circuit layers to create a highly effective structure for heat management. Here’s a closer look at the four main types of MCPCBs:

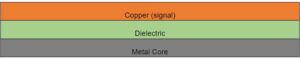

1. Single-Layer Metal Core PCB

Stack-Up: Copper – Dielectric – Metal Core

The most common type of metal core PCB, this single-layer design features a straightforward stack-up with a metal core, usually aluminum, insulated by a dielectric layer from the single copper routing layer. This simple and cost-effective structure is widely used in industrial relays and basic LED lighting solutions.

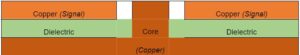

2. Thermoelectric Separation Metal Core PCB

Stack-Up: Copper – Dielectric – Copper – Metal Core

Similar to single-layer MCPCBs, but with a critical difference: the metal core, typically copper, is designed to make direct contact with the component body, while the pads are insulated by a dielectric material. This design ensures maximum thermal efficiency while maintaining electrical isolation, making it ideal for high-power LED applications. Due to its complexity, it is more expensive to produce and is used in specialized, high-performance lighting solutions.

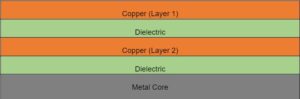

3. Double-Layer Metal Core PCB

Type 1 Stack-Up: Copper – Dielectric – Copper – Dielectric – Metal Core

This type introduces an additional copper layer, enabling more complex routing and component density. However, components can only be placed on one side. This design is common in power modules and audio equipment like amplifiers.

Type 2 Stack-Up:

Copper – Dielectric – Metal Core – Dielectric – Copper

Copper – Dielectric – Metal Core – Dielectric – Copper

Double-sided metal core PCBs allow for components on both sides of the board, offering more flexibility in design. While this stack-up reduces thermal dissipation slightly compared to single-sided designs, it allows for greater component placement, making it ideal for applications like hard disk drives and UPS systems. However, these PCBs are more challenging to fabricate than traditional FR4 boards.

4. Multilayer Metal Core PCB

Stack-Up: Multiple layers of Copper – Dielectric – Metal Core

Multilayer MCPCBs add more layers of copper and dielectric material, allowing for complex designs with blind and buried vias. However, it’s generally recommended not to exceed four layers due to the reduced thermal management efficiency caused by increased spacing between the components and the metal core. These PCBs are highly specialized, expensive to produce, and not suitable for through-hole components, but they are ideal for advanced applications requiring compact, high-density circuitry.

Each type of metal core PCB is engineered to meet specific thermal management and design needs, ensuring optimal performance across various applications. Whether you need basic LED solutions or advanced power modules, there’s a metal core PCB design that fits your requirements.

Key Applications of Metal Core PCBs

Metal core PCBs are renowned for their exceptional thermal management and mechanical durability, making them indispensable in various high-performance applications. Here are some of the key areas where metal core PCBs are widely used:

1. LED Lighting

Metal core PCBs are the go-to choice for LED applications due to their superior heat dissipation capabilities. LEDs generate significant heat during operation, especially in high-power LEDs, where heat management is crucial. Metal core PCBs efficiently dissipate this heat, ensuring optimal performance and longevity. They are commonly used in vehicle headlights, floodlights, high-intensity spotlights, and commercial lighting solutions such as bulbs, torches, and street lights. For higher-power LEDs, thermoelectric separation metal core PCBs are preferred for even better thermal management.

2. Power Switching

High-power switching equipment, such as industrial relays, heavily relies on metal core PCBs for their thermal efficiency. Metal core PCBs are also extensively used in power supply equipment, including high-voltage AC-DC converters, where effective heat dissipation is critical to maintaining stable operation and preventing overheating.

3. Automotive Electronics

In the automotive industry, electronic components often operate in high-temperature environments. Metal core PCBs are ideal for automotive electronics because they help maintain optimal operating temperatures, even in extreme conditions. For instance, the Engine Control Unit (ECU), which is typically located near the vehicle’s engine, benefits from the heat-dissipating properties of metal core PCBs. Additionally, metal core PCBs are used in automotive lighting systems, including headlights and tail lamps, to ensure reliability and performance in demanding conditions.

Metal core PCBs are essential in applications where effective heat management and mechanical strength are paramount, making them a vital component in industries ranging from lighting and power supply to automotive electronics.

Why Choose LEAPPCB as Your HDI PCBs Partner?

LEAPPCB IS a leading provider of high-quality metal core PCBs, delivering top-notch services that meet the most stringent international standards. Here’s why we are the preferred choice for your metal core PCB needs:

Proven Expertise

With over 16 years of experience, LEAPPCB has earned the trust of more than 1,000 clients worldwide. Our reputation is built on delivering exceptional quality and service, particularly to small and medium-sized businesses seeking reliable, one-stop solutions for their PCB needs.

Competitive Pricing

China is renowned for offering the best manufacturing prices without compromising quality, and LEAPPCB is no exception. We provide competitive pricing on metal core PCB fabrication services with no minimum order quantity, helping you optimize your project budget without sacrificing dependability.

Quality Assurance

At LEAPPCB, quality is our top priority. We operate under a stringent control management system, holding ISO9001:2015 and UL certifications to ensure that every step of our manufacturing process meets the highest standards. Our meticulous attention to detail and commitment to excellence guarantee superior results in every PCB we produce.

Fast Delivery

We manage product flow with precision, from material acquisition to final delivery. Our robust contingency plans ensure that unexpected challenges—such as material shortages, machine issues, or shipping delays—are swiftly addressed, ensuring timely delivery to our customers.

Post-Sales Support

Our dedicated customer service team is always available to assist with any inquiries and provide updates on your orders. Additionally, our lifecycle management team offers outstanding post-purchase support, helping you with maintenance and upgrade management for future generations of your products.

Choose LEAPPCB for your metal core PCB needs and experience the difference that expertise, quality, and exceptional service can make.

Get Your Free Instant Quote Today!

Leap Electronic is your trusted partner and one-stop shop for PCB fabrication, component sourcing, PCB assembly, and electronic manufacturing. With over 16 years of expertise, we proudly serve over 1000 customers worldwide, delivering top-quality PCBs at competitive prices. Our ISO9001:2015 certification and UL listing ensure that all our products meet the highest industry standards. Every PCB is 100% E-tested and inspected using AOI and X-RAY, guaranteeing unparalleled reliability and performance.

Don’t wait – get an instant quote from our sales team today and experience the Leap Electronic difference. We’ll handle the rest!

Everything You Need to Know About Metal Core PCBs

No, not all Metal Core PCBs (MCPCBs) are limited to a single layer. While single-layer MCPCBs are common, there are also double-sided and multilayer metal core PCBs available. Additionally, thermoelectric separation MCPCBs can be produced to meet specific thermal management needs

A standard metal core PCB typically includes the following three components:

- Metal Base: This can be aluminum, copper, iron, or another metal, providing the core structure.

- Dielectric Layer: This layer ensures electrical insulation between the metal base and the copper circuitry.

- Copper Trace: The copper trace layer handles the electronic functions, forming the conductive pathways for the circuit.

While both metal core PCBs and FR4 boards are rigid and widely used, they differ in several key ways:

- Materials Used: Metal core PCBs utilize a metal base such as aluminum, copper, or other alloys, whereas FR4 PCBs are made with a fiberglass (glass fiber) core.

- Applications: Metal core PCBs are specifically designed for heat dissipation, making them ideal for high-power applications like LED lighting. In contrast, FR4 PCBs are versatile and widely used across various electronic devices.

The thermal conductivity of MCPCBs varies depending on the materials used, ranging from 1W/m·K to 400W/m·K. This high thermal conductivity makes MCPCBs especially effective in managing heat in demanding applications.